JAMESTOWN TEST CENTER

INNOVATION SURVIVES

INNOVATION SURVIVES

only when people believe in their

OWN IDEAS

Heat Transfer

Dedicated wind tunnels with computer connectivity allows the measurement of heat rejection and internal and external fluid pressure drop using the component and engine cooling module heat transfer test. This credible data serves as the base for cooling module simulations further supporting Climatic Vehicle Wind Tunnel Testing. Using this information, the maximization of the individual heat exchanger & cooling module system performance becomes possible. This provides a simple, easily repeatable test which can be performed in continuous conformance testing to ensure the provision of the expected heat transfer over the entire time span of the product by the TitanX Heat Exchanger.

Durability Testing

High application temperature and pressure destructive forces on cooling systems can be reproduced successfully at TitanX owing to our best in class facility. We strive continuously to ensure the upgradation of our testing capabilities in order to accurately simulate the increasing temperatures of modern engines as well as their applications.

Vibration Test Facilities

Simulation of years of usage can be facilitated in a matter of hours on a test bench by the TitanX engineering team after the collection of test track data. We provide 3 types of vibration tables wherein pressurization & thermal cycle load can be added to vibration testing for better simulation of field conditions:

- Degree of Freedom (DOF)

- 6 DOF & NARLY

- TitanX’s 7 DOF

TitanX’s 3 translational & 3rotational DOFs with a chassis twist is known as NARLY. It incorporates load cells for all actuators thereby providing us with excellent capability for modal analysis of complete cooling modules as mounted in a vehicle.

Field and Laboratory Data Recording

Jamestown Division’s field and laboratory data recording has a diverse range of capabilities like:

- eDAQ system with 48 HLS

- 8 thermocouple and 24 low level channels conditioning

- Sensors for 50 acceleration

- 40 strain channels pressure

- Displacement transducers

Data processing is done using Glyphworks and inField, while modal analysis is performed using ME-Scope.

Chemistry/Metallurgical Laboratory

At TitanX, we are equipped with state of the art, two staffed chemical and metallurgical laboratories capable of providing intelligent internal & external customer support for microscopic, thermal, chemical and physical analysis of metals, polymers and elastomers. Our simulation models are incorporated with this data as well. The metrology laboratories can provide layout inspection on cooling modules and components to help ensure proper installation.

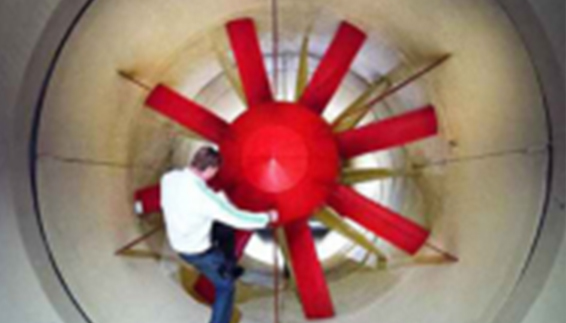

Vehicle Climatic Wind Tunnel

Our climatic wind tunnel facility is located in Jamestown, NY USA which is used for the development of engine cooling & climate control systems for heavy truck manufacturers. TitanX engineers use this high-quality facility under controlled conditions to optimize product performance under a wide range of operating conditions. These climate-controlled wind tunnels can also be used for the climatic testing of other vehicular systems such as fuel, brakes and other non-vehicle applications. We work with a highly skilled team of engineers experienced in working with customers for the development of standard as well as customized testing programs.